Date – 5th April 2020

Topic: Volatile Organic Compounds Abatement from the Environment: Selecting the Appropriate Technology

Venue: WhatsApp Group

Presenter: Engr. Abdullahi Mohammed Evuti

Presenter’s Profile

Abdullahi Mohammed Evuti is a Chemical Engineer with experience in teaching, research and consultancy practice in Chemical Engineering. A PhD graduate (Chemical Engineering) from Universiti Teknologi Malaysia (UTM), Skudai-Johor, Malaysia with First Degree (B.Eng) in Chemical Engineering from Ahmadu Bello University, Zaria-Nigeria (1994) and M.Eng in Chemical Engineering from Federal University of Technology, Minna-Nigeria. Registered Engineer with the Council for Regulation of Engineering in Nigeria (COREN, R16,044). He served as a Lecturer in the Department of Chemical Engineering, Kaduna Polytechnic, Kaduna-Nigeria from 2000 to 2008 before moving to the University of Abuja-Nigeria. He was promoted to the rank of Associate Professor of Environmental Engineering in 2017. He has served as a member of many university committees and in a leadership capacity as the Head of Department of Chemical Engineering from 12th of May, 2015 to 27th of June, 2019. His skills as a team player contributed to the successful accreditation of the Chemical Engineering program in 2015 which earned the department a commendation from the Vice-Chancellor. He is presently the Deputy Dean of the Faculty of the Engineering University of Abuja-Nigeria. He has also served as a panel member/chairman of the Ministerial Committee set up by the Hon. Minister of Environment to review the draft EIA Report for several proposed plants nationwide. He is presently a member of the governing of ILA College of Health Technology, Kuje-Abuja.

Research Interests

Engr. Dr. Abdullahi Mohammed Evuti has through his interest, years of academic training and research experience established and strengthened his expertise in water and wastewater treatment and environmental pollution control. Other research interests include energy from biomass, volatile organic compounds treatment from air and wastewater, climate change and carbon emission control, environmental impact assessment (EIA), Environmental Audit, Hazard operability studies (Hazop), soil remediation and general Chemical Engineering practice

Some Related Research works carried out

- Treatment of Toluene and Xylene Compounds from Wastewater using Air stripping and Non-thermal Plasma system.

- Analysis of Electrical Energy Consumption and Greenhouse (GHG) Emission at the University of Abuja main campus.

- Enhancement of remediation of petroleum polluted soil at Suleja depot using linear alkylbenzene sulfonate

- Functionalized Activated carbon from coconut shell for the treatment of methylene blue and Congo red simulated aqueous solution

- Application of multi-criteria analysis in oil spill management in Nigeria

- Application of air stripping in the treatment of petroleum contaminated soils.

- Development of Nano-Composite Adsorbents from Agro-Wastes for Removal of Heavy Metals for Industrial Wastewater Treatment

PREAMBLE

As environmental impact assessment practitioners, we know that a vital section of the EIA report is the process description. In this section, we come across different process equipment depending on the type of projects. The performance of this equipment determines the type of likely impact the project will have on the environment. Hence the significance of today’s topic.

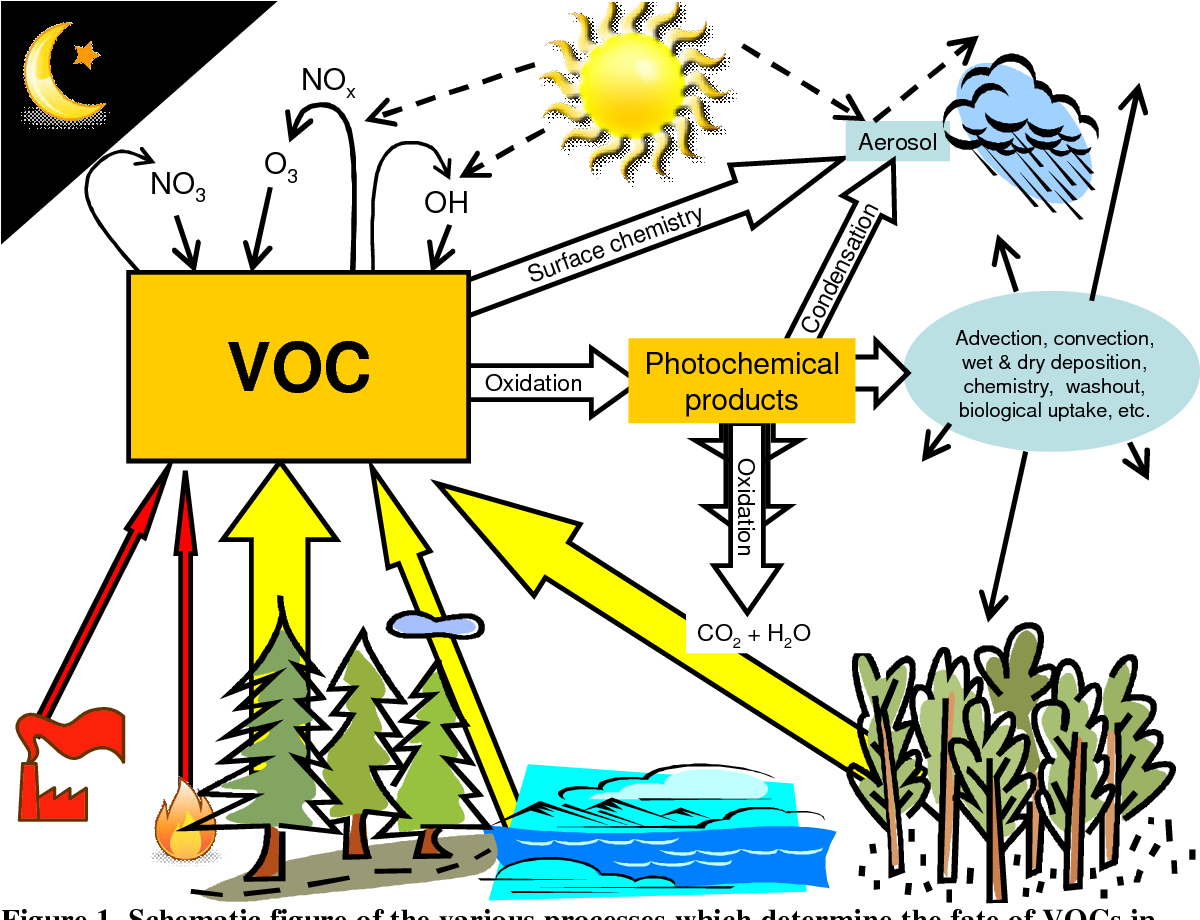

Volatile organic compounds (VOCs) are dangerous to human health and also trigger serious environmental problems such as ozone layer depletion, offensive odor, photochemical smog, and acid rain.

Out of 189 hazardous air pollutants (HAPs) identified by the United States Environmental Protection Agency (USEPA), 97 are VOCs

Three factors determine the severity of a pollutant:

- Its chemical nature,

- The concentration and

- The persistence

Biogenic VOCs are produced by plants, animals, microbes, and fungi while anthropogenic VOCs are primarily emitted by chemical process industries (CPI) dealing with the manufacture, storage, handling, and distribution of paints, lubricants and liquid fuels; and the combustion processes. With continued global industrialization, the atmospheric concentrations of VOCs due to primary as well as fugitive emissions have constantly been on the rise

Selecting an appropriate technology for the treatment of VOCs from wastewater from a range of possibilities is the key to successful operation. Although this is understood by many, people often underestimate how difficult the choice can be. The various constraints have been summed up into a concise acronym for analysis called ‘SHTEFIE’ criteria. This acronym stands for Social, Health, Technological, Economic, Financial, Institutional and Environmental constraints. This heuristic algorithm for analysis was originally developed at Loughborough University as a tool for the evaluation of various development program alternatives. This presentation will involve discussion of various volatile organic compound (VOCs) abatement technologies such as air stripping, adsorption, membrane technology, anaerobic/aerobic biological treatment, advanced oxidation processes; their applicability and limitations and how to use SHTEFIE criteria in choosing appropriate technology.

Appropriate technology is defined as “technology that is suitable to the social and economic conditions of the geographic area in which it is to be applied, is environmentally sound, and promotes self-sufficiency on the part of those using it”.

The concept of Appropriate Technology (AT) stemmed from the work (the book “Small is Beautiful – Economics as if people mattered”) of British economist Dr. Fritz Schumacher in the 1970s. He argued that technology should be designed in ways that would promote health, beauty, and permanence. He was principally concerned with the development in low-income countries and recommended a technology that was aimed at helping the poor in these countries to do what they were already doing in a better way.

Appropriate technology should, therefore:

- Meet people’s needs,

- Help protect the environment,

- Use local skills and materials,

- Help people earn a living,

- Be affordable and

- Pave the way for a better future.

It should be noted that not all technology is relevant and appropriate. For example, highly complex engineering solutions are sometimes imposed on unwilling local people. A state-of-the-art tractor might enable higher productivity than a horse-drawn cart, but when the tractor breaks down, spare parts are not always available, nor are the skills to carry out the repair – a high technology solution becomes effectively useless.

VOCs Treatment

Methods of treating VOCs include

- Air stripping – based on increasing the surface area of the contaminated water by exposing it to air. However, air stripping is only a mere phase separation and the off-gas from the air stripper may have to undergo further treatment (such as adsorption, catalytic oxidation, or incineration) to meet the emission standards.

- Adsorption,

- Membrane technology,

- Electrochemical technology,

- Anaerobic/aerobic

- Biological treatment and bioreactor

- Advanced oxidation processes

- Plasma technology,

- Integrated (hybrid) systems

Selection of the best treatment method is dependent on:

- VOC characteristics (biodegradability, concentration, volatility, and solubility),

- pronounced flexibility,

- high removal efficiency,

- low capital and operating cost,

- the volume of VOCs to be treated and

- possibility of VOC recycling.

When a single VOC is present in high concentration, a separation/recovery method is preferred, while a destruction method may be best for the disposal of mixed VOCs.

When a single VOC is present in high concentration, a separation/recovery method is preferred, while a destruction method may be best for the disposal of mixed VOCs.

Stages in the application of ‘SHTEFIE’ criteria

Stage 1: Objectives: The purpose of the process must be established.

Stage 2: Analysis: The constraints should be identified. What are the limitations of each method? The factors to be considered include:

- Social

- Health

- Technological

- Economic

- Financial

- Institutional

- Environmental

This may be simplified by drawing a checklist of factors to be considered and from this, a professional judgment is made.

Stage 3: Output: The output will clearly answer the question as to what particular technology is appropriate.

This ‘SHTEFIE’ criteria can be applied by any EIA practitioner in assessing any equipment that he encounters during his work. He may be able to best advise his client or suggest appropriate mitigation measure

Q – I will like to know if, in your course of EIA reviews, you have been comfortable with the BATs and BPTs that Nigerian Proponents advance in their proposed project developments?

A – Sometimes NO. But from my experience as a panel member, I do observe inadequate information and the consultants do claim that the proponent is hoarding information

Q – 1. How adequate are VOC standards/limits in Nigeria; and 2? In your experience, how can we improve on the grab sampling approach to VOC sampling (actually air quality and noise in general) without resorting to the rather much more expensive continuous monitoring approach?

A – There should be a period review particularly as new knowledge on the physio-chemical characteristics of these chemical compounds emerges.

Q- In most studies concerning the treatment of VOCs from wastewater, aromatic hydrocarbons, notably benzene, are more readily released from the wastewater into the atmosphere, whereas the chlorinated compounds except chloroform are mainly present in the water phase through the treatment processes.

Why is this so sir?

A – National pollution inventory defined VOCs as any compound based on carbon chain or rings (and also containing hydrogen) with a vapor pressure greater than 0.01 kpa at 20 0C. Also, it is defined as an organic chemical with a high vapor pressure at ordinary, room temperature conditions. This is due to their low boiling points, which causes large numbers of molecules to evaporate from the liquid or solid form of the compound into the surrounding air. VOC undergoes complex photochemical reactions in the presence of sunlight and oxides of nitrogen to form ozone, a major component of urban air smog. Ozone is produced from the photolytic decomposition of NO2 when the oxygen atom formed rapidly recombines with molecular oxygen.

Q – Thank you Dr. Evuti for a beautiful presentation; can you please throw more light on ground-level ozone; the reaction of VOCs and other gases such as NOx etc?

A – Ground-level ozone is of concern not only with respect to human health but also because of its effects on crops, plants, and trees. persistent organic pollutants (POP) are best treated using destructive techniques such as plasma technology Plasma is an ionized (electrified) gas with a chemically reactive media consisting of energetic electrons, positive and negative ions, free radicals, metastables, gas atoms and molecules in the ground or excited states Plasma is an ionized (electrified) gas with a chemically reactive media consisting of energetic electrons, positive and negative ions, free radicals, metastables, gas atoms and molecules in the ground or excited states.

Q – Sir I want to ask you this question. In terms of cumulative impact assessment in EIAs, do you NOT think it’s sheer waste to consider just VOCs without their potential chemical reactions with other gases such as NOx? For instance, when VOCs and NOx meet in the presence of sunlight/UV rays they form the ground-level ozone (bad ozone), and they become synergistic (a type of cumulative impact) and have much more severe negative impacts on human beings and plant and animal species. What’s your experience in addressing such this thus far in EIA?

A – Thank you. This will vary from one process plant to another depending on the process involved. sometimes you encounter only one VOC and sometimes more. This will determine which technology to apply or to consider the cumulative effect of their reaction